Energy Efficient Stuff , Low Energy Housing , Net Zero Energy Homes , Sustainable Home Design

What Do You Get When You Mash Up A Refrigerator Box, A Trailer, A Sleeping Bag, and a Thermos?

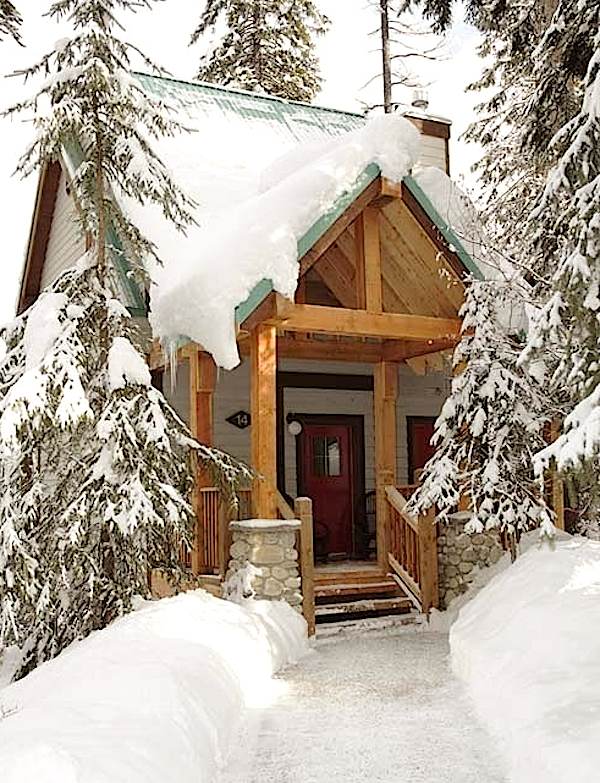

Notice the steep pitched metal roof. The snow has slid and/or melted off the peak, but there’s still a deep blanket on the rest of the roof, meaning there’s great air sealing and a lot of insulation under it!

You get a Tiny House that works in cold climates!

In 2015, I did a presentation for the NS Tiny House Movement Meet Up group.

I flagged some of the issues I saw in terms of cold climates and energy efficiency and how to solve them for tiny houses.

Here’s the presentation. I’m planning on expanding it and adding a couple of case studies, along with a voice over and an interview or two.

Let me know what information you’d like to have added!

Mindscape Innovations posted this notice in their recent newsletter: SB-12 (2017) Updates are up and ready for your input. Comments are due before March 11, 2016.

Here are the documents you need to review:

1) Draft MMAH SB-12 (2017) Version

2) Background Document and Comment Form

Here’s the summary of the key changes, from MI’s newsletter. Big flag on the last one: Drainwater Heat Recovery Tradeoff has been removed.

Key Changes Proposed for 2017 Version

- 15% Energy Efficiency Improvement: Each SB-12 package is designed to be 15% more energy efficient than current SB-12 packages, based on an ‘average’ home.

- Fewer Packages: To reduce redundancy of unused packages in the current version, the proposed number of prescriptive packages will be less, e.g. 6 instead of 13 for the scenario of Zone 1 – Natural Gas.

- Now in Metric! Metric thermal values are now included in addition to imperial. Metric continues its slow and steady march to global domination

- Effective Thermal Resistance: Minimum thermal performance values for various assemblies are now listed in both nominal and effective. This will give a boost to buildings that use exterior continuous insulation, well the actual performance of the entire assembly, including thermal bridging through the studs, is recognized.

- Mandatory Heat Recovery Ventilators: Heat Recovery Ventilators is proposed to be mandatory across all packages, in order to facilitate better indoor air quality in airtight homes.

- Credit for Reduced Air Leakage: Recognition for demonstrating increased airtightess of the building envelope with a blower door test has been added. Improved airtightness can be used as a substitution for various insulation upgrades.

- Drain Water Heat Recovery (DWHR) Tradeoff has Been ‘Discreetly’ Removed: While MMAH doesn’t specifically indicate this in the list of proposed changes in their Backgrounder document, the proposed SB-12 (2017) update has been scrubbed of all traces of DWHR: where builders currently have the option of being credited for including DWHR by trading off another upgrade, they will no longer have this option under the drafted SB-12 (2017) update.

Go to the Mindscape article for the full details and a solid argument for keeping DWHR in SB-12 (2017), and pass it along!

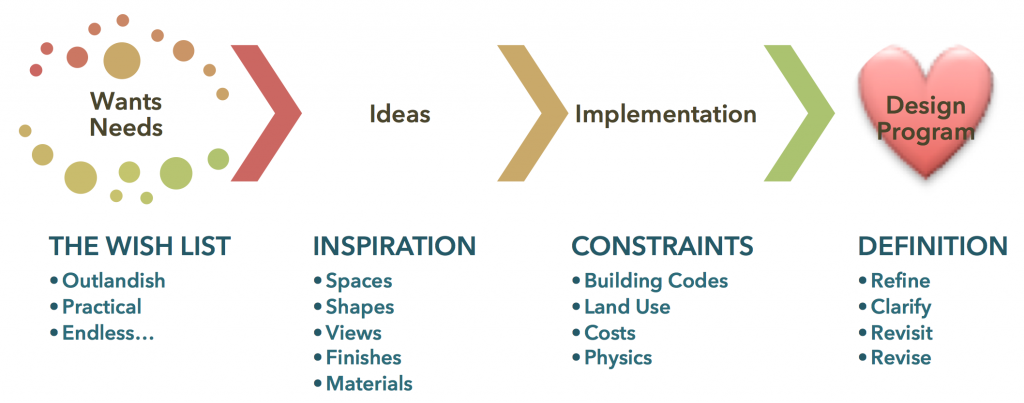

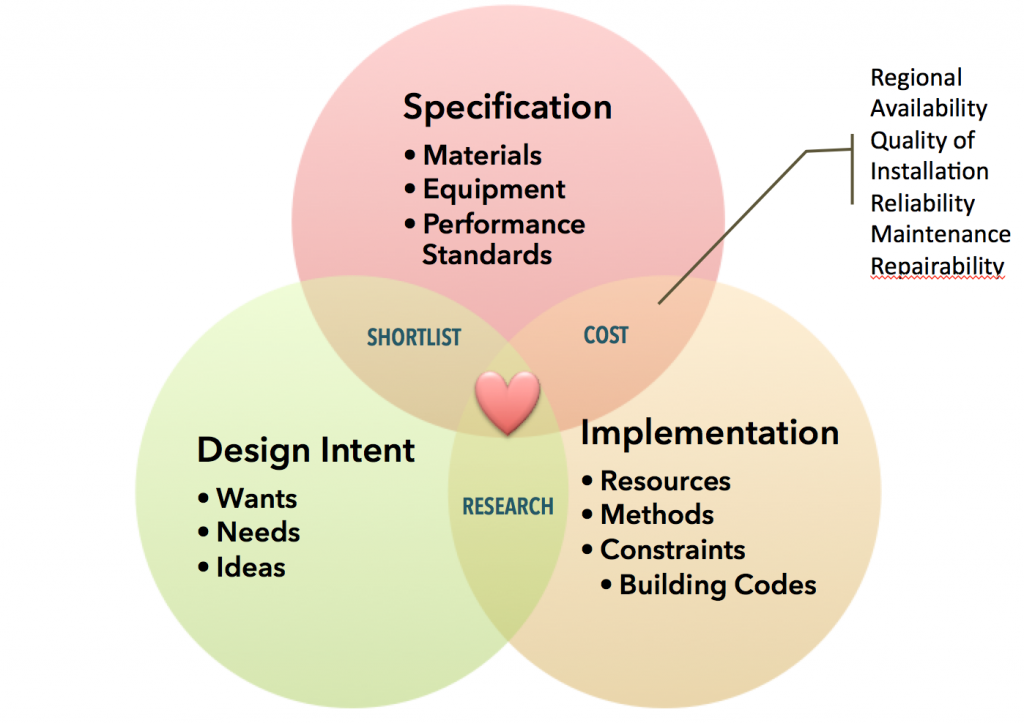

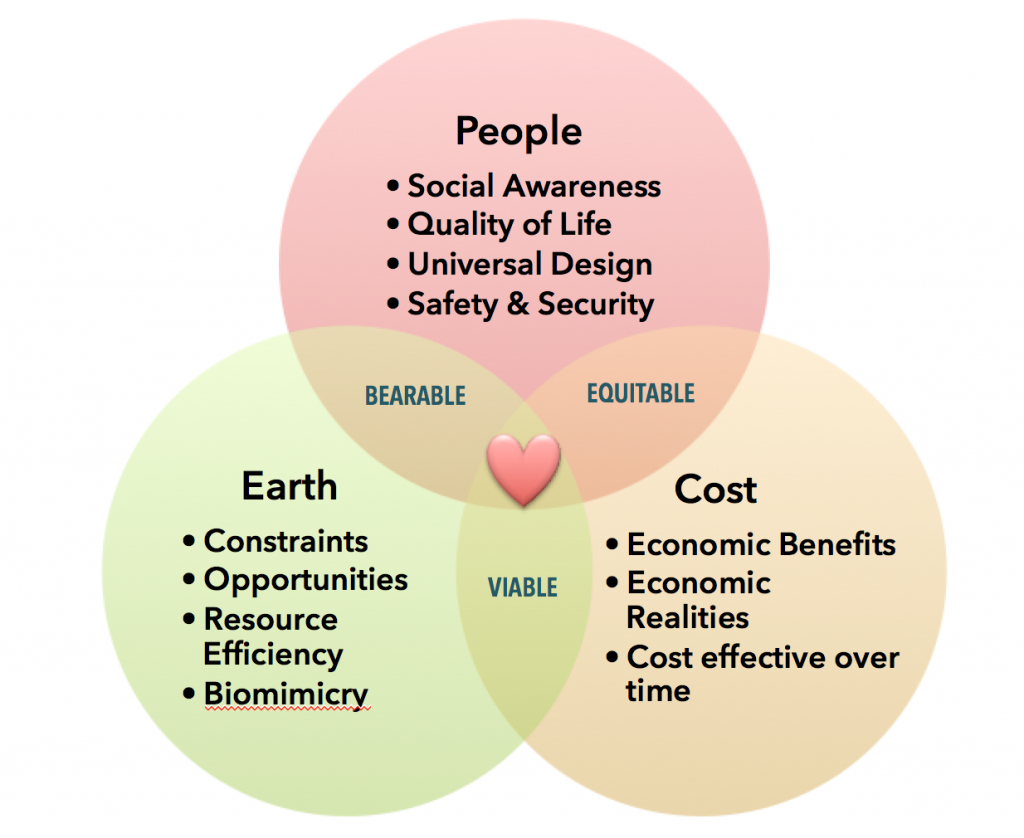

Designing a house or a renovation to an existing house is a complicated process, with many different aspects to consider.

In the broadest sense, it is moving from idea to the plans for the finished project.

All sorts of elements need to be considered, researched and evaluated for every decision to make the design attainable.

Add the elements of sustainability into the mix, just to make it a little more complicated.

The process is really a spiral that loops back and forth, where ideas, obstacles, options, and solutions in one area affect ideas, obstacles, options, and solutions in any other area. Design is about finding the connections and synergies between things that seem like they couldn’t possibly be related.

Write about Sustainable Design.

There’s a lot to write about. Over the years that I have been consulting with homeowners on how they can reduce energy and water use, make greener choices in materials and construction technology, ensure that their space planning is barrier free, user friendly and ready for aging-in-place, I’ve gathered a lot of experience and resources.

Some of it has made it’s way into the Canadian Solar Home Design Manual and the online courses we offer through Blue House Energy, but lots of it is still in my head, especially the cool stuff like Net Zero Energy New Construction and Deep Energy Retrofits. Integrating renewables, bucking the trend and going for a stupid, not a smart, home…

The design process is never a straight line from start to finish, and there’s a lot more to think about when you add sustainability into the mix.

We constantly hear people say: I have my energy evaluation but what do I do now? Who should I get to do the work? What should I do first? Last?

When it comes to energy efficiency, there’s a lot of information and noise out there to sift through. We can cut through all of that. We don’t sell any products, so we’re not biased one way or another.

Except when it comes to homeowners.

We’re totally biased.

We are completely on your side and want to help you get and stay warm and comfortable, with lower energy bills. We can help you make decisions about upgrades and improvements quickly and effectively.

We’ve found that we can be really helpful in a short and focussed house visit, and most people just need a little coaching to get going.

So, we have a new Energy Coaching service in HRM and surrounding areas.

You get:

• 60 minutes of expert time at your house

• A roadmap of what to do, and in what order (this is super important)

• A roster of contractors we trust to do good work

• Links to ‘best practices’ videos and guides for DiY types

Check it out here

While hard-surface flooring is on every list for improving indoor air quality, the type of hard-surface flooring may be problematic, especially if your clients’ health is already compromised.

This article on formaldehyde levels in laminate flooring emphatically waves the health flag. The article is based on testing of Chinese-made laminate flooring. The testing was done by the Hardwood Plywood and Veneer Association. The article doesn’t make it sound very rigorous…“We went into a retail store and grabbed a sample, tested it and six out of eight flunked,” says Kip Howlett, President of the HPVA, an industry association that represents some Canadian and American flooring manufacturers.

So let’s be fair, any processed wood product (be it laminate flooring, pre-finished flooring, a particle board vanity) that has been taken off the factory floor, shrink-wrapped and held in storage is going to offgas like crazy as soon as it’s unwrapped and exposed to the air. Even apples and apricots offgas naturally occuring formaldehyde. So let’s be very precise: urea formaldehyde (vs. phenol formaldehyde) is the problematic product here. Urea formaldehyde is an inexpensive glue used to bind wood products.

I’ve heard/read/been told/taught that offgassing of VOCs and/or urea formaldehyde from processed wood products is worst at the exposed cut edges, not the formed portion of the processed board, and that the rate/extent of the offgassing is relative to the temperature of the product and ambient air. While the exposed edges on laminate flooring planks are a very small proportion of the overall product, and are not exposed to air movement when installed, laminate flooring has become very popular in houses with in-floor heating systems. Which could be a problem, except the exposed surface of the laminate is not the processed wood substrate or its cut edges. It’s the laminate — which could have a whole whack of other IAQ impacts, but I’m not going there right now. I haven’t yet found 3rd party monitoring that indicates the urea formaldehyde loads in a room with freshly installed/aged laminate flooring regardless of what country it hails from.

It all leads to questions about the testing rigor, testing protocols, actual in-situ loading, and what levels a range of manufactured floor products from a variety of countries would test out out at…I’m gonna find me some more data points.

Yes, yes, it’s me!! Pretty chuffed with myself. Send suggestions for articles, notes about cool projects you’re working on, Net Zero Energy/Deep Energy Retrofit initiatives in your area via this link.

Energy Efficient Stuff

Nova Scotian Homeowners — interested in estimating your electricity usage?

NS Power has a dandy little calculator that covers nearly all the bases. You’ll have to think a bit about your energy use, but that’s probably a good thing, right? How many hours a day do you typically have how many lights turned on? Do you leave computers and printers and other electronics on standby?

How much of a phantom load are you paying for? And how are you going to determine what’s using the energy that you shouldn’t be paying for?

Kill-A-Watt meter — lets you see how much energy any plug-in appliance, electronic device or thingy uses. Great for identifying your phantom loads.

I have two Kill-a-Watt meters, they plug into the wall socket and then you plug your electrical device into them. The meters show what the draw is, and you can see how much electricity things like a fridge or a freezer use over a 24 hour period in kWh or $$ (or both). I’ve also used them throughout the house to determine what our always-on devices give us for phantom loads. But some things (water heaters and baseboards) for example, you can’t plug in. I’ve been very interested in monitoring systems for a long time, but haven’t been able to justify one for my household.

That just changed.

I’ve signed up to be a beta tester for a monitoring system by Blueline Innovations (St Johns, NL) that uses a sensor on our meter to send energy use information to our wireless devices. We’ll see if we can reduce our energy usage through behavioural changes! Will report on our success or failure after the 90 day testing period.

If you’re interested in participating in the beta testing program too, email: beta@bluelineinnovations.com

Deep Energy Retrofits , Energy Efficient Stuff , Indoor Air Quality

Risks Associated with Poor Spray-Foam Installations

‘Leathery’ spray foam has lost it’s air pockets and is no longer effective. Is it inert in this condition?

A few months ago, I posed a question about spray foam installations and wet wood to some of the forums I belong to.

I got an astounding response — some of it snarky, most of it super helpful. I’m still editing a longer piece that will cover the responses, but in the meantime I ran into this:

Squishy, deflated, leathery 2lb foam. This was installed on the leaky concrete wall of a basement stairwell with a partial foundation, with a connection to an unflashed framed wall above. The house was built in 1836, while the stairwell was obviously a much later addition. The foundation is very wet, the tidelines on the mechanical equipment hitting the 8″ mark, and obvious water markings on the exposed part of the original rubble foundation. After reading all the comments from my original question about spray foam installations and the considered responses, I have to ask myself what spray foam contractor worth their salt would install in such conditions?

The water damage is easily seen throughout the rubble basement walls. The insulation was sprayed onto the top 24 to 36″ of the rubble wall, but has lots of voids and cracks. There is also a wide range of spray consistencies visible — some of the foam looks positively cumulous, while other parts look like smooth lava. Rookie installer? D-I-Y install from a kit system? Who knows — the homeowners purchased this spring and have no records.

From a cursory walk around the perimeter of the house, I knew there would be one fixable source of water leakage into the foundation: over the 175 years, the grade had settled (dramatically in some places), and snow melt and rain water were caught and funneled down into the rubble wall. Straightforward solution to that cause: regrade. Other problems with the foundation, not so straightforward, but we’ll see.

The state of this spray foam made me wonder about health issues, because it had so obviously perished and was dripping this ghastly caramel coloured ooze. There is some field research being done to look at the risks associated with installing spray foam (Field Research to Provide Deeper Look at Spray-Foam Risks – BuildingGreen), but I am not familiar with any studies published on long-term health risks to occupants as a result of crap installations like this one. There are substantiated issues with offgassing immediately after installation, yes, but let’s assume that the product performs as its data sheet indicates, and 24 hours sees most of the offgassing dissipate in a properly done installation.

Water penetration in walls is a problem, period, regardless of the type of insulation that is used, so I’m not freaking out on one type of insulation. From many, many problematic basements, we know what is likely to happen in below-grade frame wall cavities filled with fiberglass batt insulation. When the fiberglass gets wet, it doesn’t drain well or dry out and so causes mold growth given enough warmth. That causes health problems. Cellulose is a total no-go below grade for the same reason. As far as I’m concerned, rockwool is the best option for fibrous insulation below grade. Or spray foam. But only once the foundation is dry. There are so many indoor air quality and eventual structural problems that can be minimized or eliminated by eliminating water leakage into the foundation, and so many that can become exponentially worse by NOT eliminating water leakage into the foundation.

Low Energy Housing , Net Zero Energy Homes , Stuff that makes me crazy

How zero is net zero…what’s not changing?

So there’s lots of excellent work and capacity building going on and Net Zero Energy and Low Energy and High Performance houses are being designed and built throughout North America. Innovation and forward thinking abound. It’s all very exciting. But there’s a place past which most builders, designers, and homeowners will not go: beyond low-flow plumbing fixtures, specifically toilets. Massive infrastructure has made it pretty convenient to not think about the consequences of flush toilets. Sure, there are problems with effluent and e.coli and we have to treat water severely before it can be classed as ‘clean’ once we flush it, but there are engineering solutions for that, and there’s lots of money tied up in that, and this system works just fine, thanks, with a few extra jolts of chlorine added every once in a while.

But really, no. There are big issues. This is not a good version of an open system. Piped water is a great convenience and a massive boon to public health, at the same time that it’s a disaster for the environment.

Water usage and access to potable water is in my mind a lot right now, with water rate hikes, and low-income households in Detroit having their water turned off due to one missed payment (yet 80% of the unpaid bills are corporate customers), and the looming potential of privatization of water resources. Tank Girl anyone?

Water shut-offs at the city scale, like what’s happening in Detroit (hey, kick ’em while they’re down, whydoncha?), are likely precursors to major health problems, to homes being made uninhabitable, and to state-sanctioned removal of children from their homes. How is that cost-effective? What are people going to do? Where are they going to go (in so many ways, where are they going to go), and how does the city expect to garner property taxes out of more derelict, abandoned houses? It’s a painful situation where solutions need to be found, and quickly, but this plays out quickly in my head as a worsening situation not an improving one, not even in the short run.

This article, by Lloyd Alter, managing editor of Treehugger, does a good job of dissecting problems with the North American approach to piped water and poop. I like his observation that the modern bathroom hasn’t changed much since 1910: small room, porcelain fixtures, line everything up in a row to use less pipe. Done.

Ya, except is this the best way to do it?

Critical analysis would indicate not: just from a health point of view, flushing a toilet sends reams of bacteria into the air. And sinks are right beside toilets. And toothbrushes are right beside sinks. Ew.

And there’s more: toilets are designed for sitting, we’re designed for squatting…ergonomics 101 have not been applied to the standard bathroom layout or fixture design. But we do have have an engineering solution.

But flushing is the big thing that circles back to my concerns about piped potable water usage and energy use and costs (not to mention the burden on aquifers and such): flush toilets result in millions of gallons of clean, potable (ie, drinkable) water contaminated, churned up and redistributed for your swimming pleasure. Ew. It wouldn’t be quite so bad if the blackwater (toilets) and greywater (pretty much everything else) were separately treated. Then at least the lightly contaminated greywater could be treated in a different manner that quite possibly would be less energy intensive, bringing down the overall amount of energy required to treat water (from Alter’s article: 10 bn litres of sewage/day in England and Wales requires ±6.3 GW hours of energy to treat, nearly 1% of daily electrical consumption for the two countries).

What if there were no blac kwater? If there were no flushing…

kwater? If there were no flushing…

Compost toilets have been around for a long time — I first read about them in my cherished 1981 first edition of ‘More Homes and Other Garbage: Designs for Self-sufficient Living‘. Clivus Multrum was then, and still is, the Cadillac of Composting Crappers.

It could be time to re-write Witold Rybczynski’s classic from the ’70s ‘Stop the Five Gallon Flush‘ (That book was out of McGill, it was brilliant, and yes, I have a copy), as ‘Stop the Flush’.

Except of course, people would be responsible for their own shit.

That could be awkward.

Or it could be a re-learning of how open systems work — you have an environment, there’s input from the environment, there’s throughput, and there’s output back into environment, feedback comes from the environment and allows for changes that allow for survival and growth.

THAT would be fine.

Leave A Comment